Industrial Crushers

Leading Manufacturers, Exporters, Wholesaler and Retailer of Cone Crusher Spare Parts, Granulator Crusher, Jaw Crusher, Roll Crusher and Rotopactor Crusher from Siliguri.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | UBH Industries |

| Country of Origin | India |

| Type | Cone Crusher Spare Parts |

| Material | Various Materials Including High-grade Steel And Alloys |

| Packaging | Depends On The Specific Spare Part |

| Application | Replacement And Maintenance Of Cone Crusher Components |

| Key Features | High Crushing Efficiency,Optimized Feed Flow For Reduced Power Usage And Maximum Throughput.,Robust Construction,Heavy-duty Components For Performance Under Extreme Conditions.,Hydraulic Settings Adjustment,Fast And Easy Setting Changes For Precise Output |

| Available Spares | Concave & Mantle Liners,Eccentric Bushings,Countershaft Assemblies,Head & Main Shaft Assemblies,Adjustment Rings & Seals,Bearings & Gear Sets,Dust Seals, Toggle Seats, And More |

| Quality Testing | Components Are Tested For Quality And Durability. |

Cone Crusher Plant & Spares – Power, Precision, and Performance by UBH Industries

At UBH Industries, we offer complete solutions for Cone Crusher Plants that deliver superior crushing performance, reduced operational costs, and exceptional durability. Designed to handle high-volume material with precision, our cone crusher systems are ideal for secondary and tertiary crushing in mining, aggregates, stone quarrying, and construction applications.

Whether you 're setting up a new cone crusher plant or looking for reliable spare parts to keep your operations running smoothly, UBH Industries is your trusted partner. We provide end-to-end installation support, robust machine components, and a wide array of precision-fit spares from top brands – all backed by our commitment to quality and customer satisfaction.

Key Features of Our Cone Crusher Machines:

- High Crushing Efficiency

Advanced design allows for optimized feed flow, reducing power usage while maximizing throughput. - Robust Construction

Heavy-duty components engineered to perform under extreme conditions and extended use. - Hydraulic Settings Adjustment

Allows fast and easy setting changes for precise output sizes without shutting down the plant. - Anti-spin Mechanism

Prevents head spin to reduce wear and enhance machine life. - Automatic Overload Protection

Safeguards the crusher from damage during tough crushing tasks or material overloads. - Excellent Cubical Output

Ensures better shaping of aggregates – ideal for roads, concrete, and building applications.

Cone Crusher Spares – Premium Parts for Peak Performance

UBH Industries supplies a wide inventory of genuine and aftermarket cone crusher spares, compatible with all leading brands. Our spare parts are engineered for a perfect fit, reliable functionality, and extended operational life.

Available Spares Include:

- Concave & Mantle Liners

- Eccentric Bushings

- Countershaft Assemblies

- Head & Main Shaft Assemblies

- Adjustment Rings & Seals

- Bearings & Gear Sets

- Dust Seals, Toggle Seats, and More

All components are tested for quality and durability to ensure your machines operate at peak performance with minimal breakdowns.

Why Choose UBH Industries for Cone Crusher Solutions?

- Expertise in Plant Setup

Turnkey support for new cone crusher plant installations, including site assessment, machine selection, and commissioning. - Comprehensive Spare Inventory

Ready stock of critical parts from all leading manufacturers ensures faster service and minimal downtime. - Customized Solutions

Plant configurations tailored to your material type, capacity needs, and production goals. - Reliable Technical Assistance

Our experienced technicians offer on-site inspections, troubleshooting, and performance optimization. - Cost-Effective Solutions

Get competitive prices without compromising on material quality or service standards - Trusted Across Regions

A preferred name across North Bengal, Sikkim, Bhutan, and Nepal for industrial crushing equipment and support

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

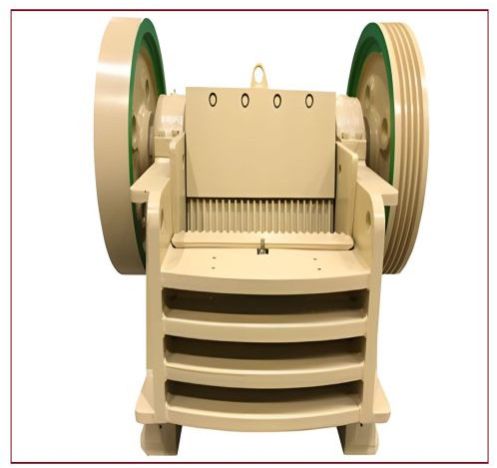

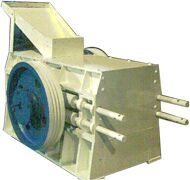

Ubh industries deal in high quality stone crushing plants and equipment and its spares to the entire satisfaction of our clients. Our products include jaw Crusher (Primary Crusher), Granulator (secondary crusher), roll crusher (bush type), belt conveyors and loaders in different sizes and designs according to the specifics requirements of customers. Our stone crushing plants range production from 20TPH to I50TPH according to the requirement of customer.

Ubh industries always supplies replacement parts, as well as regular services to our customer crushing plants in most states of India, but enjoy strong equity in Sikkim, North Bengal, Bhutan, Nepal and Assam. stone crusher machine can be used in crushing of wide range of material such as BAUXITE, CARBORUNDUM, (Silicon Carbide), GRANITE, CALCUIM, IRON ORE, MANGANESE, RIVER GRAVEL, LIME STONE, BLACK ROCK, COAL, COKE, QUARTZ.

Research and Development

We under stand the fact that to survive the stiff market competition, it is imperative for us to constantly upgrade the technology used by us for manufacturing our material handling equipment. To help us in this, we have established a modern R&D unit within our organization, which is equipped with the latest technology based instruments and equipment. These help our R&D professionals in carrying out various research projects in an effective and competitive manner.

After Sale Services

We provide efficient after sale services that is provided by our trained staff. We not only install the machines but also assist our clients with their first use. We ensure that our crusher's function properly and hence our team timely visits sites and attends to the complains, as well as provide timely servicing to the crushers. We also have in-store spare parts of each model and hence ensure perfect replacement of parts, if required.

Parts List

- Main Body

- Liver Pin

- Jaw stock (Lever)

- Jaw Plates (Reversible)

- Toggle Bearing

- Toggle Plates

- Fixed Plate (Reversible)

- Slide Plate

- Fly wheel (Flat)

- Brackets cover

- Bearing Brackets

- Eccentric shaft

- Pitman fitted roll brg.

- Fly wheel (V-grove)

- Pull back rod

- Spring

- Washer

- Fly Nut

- Wedge block & Toggle Block

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Metal |

| Type | Stone Crushing Equipment |

| Color | Light Yellow |

| Brand Name | Ubh industries |

| Primary Crusher Type | Jaw Crusher |

| Secondary Crusher Type | Granulator |

| Tertiary Crusher Type | Roll Crusher |

| Production Range | 20TPH To 150TPH |

Ubh industries deal in high quality stone crushing plants and equipment and its spares to the entire satisfaction of our clients. Our products include jaw Crusher (Primary Crusher), Granulator (secondary crusher), roll crusher (bush type), belt conveyors and loaders in different sizes and designs according to the specifics requirements of customers. Our stone crushing plants range production from 20TPH to I50TPH according to the requirement of customer.

Ubh industries always supplies replacement parts, as well as regular services to our customer crushing plants in most states of India, but enjoy strong equity in Sikkim, North Bengal, Bhutan, Nepal and Assam. stone crusher machine can be used in crushing of wide range of material such as BAUXITE, CARBORUNDUM, (Silicon Carbide), GRANITE, CALCUIM, IRON ORE, MANGANESE, RIVER GRAVEL, LIME STONE, BLACK ROCK, COAL, COKE, QUARTZ.

Research and Development

We under stand the fact that to survive the stiff market competition, it is imperative for us to constantly upgrade the technology used by us for manufacturing our material handling equipment. To help us in this, we have established a modern R&D unit within our organization, which is equipped with the latest technology based instruments and equipment. These help our R&D professionals in carrying out various research projects in an effective and competitive manner

After Sale Service

We provide efficient after sale services that is provided by our trained staff. We not only install the machines but also assist our clients with their first use. We ensure that our crusher's function properly and hence our team timely visits sites and attends to the complains, as well as provide timely servicing to the crushers. We also have in-store spare parts of each model and hence ensure perfect replacement of parts, if required.

Parts List

- Main Body

- Liver Pin

- Jaw stock (Lever)

- Jaw Plates (Reversible)

- Toggle Bearing

- Toggle Plates

- Fixed Plate (Reversible)

- Slide Plate

- Fly wheel (Flat)

- Brackets cover

- Bearing Brackets

- Eccentric shaft

- Pitman fitted roll brg.

- Fly wheel (V-grove)

- Pull back rod

- Spring

- Washer

- Fly Nut

- Wedge block & Toggle Block

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Ubh industries deal in high quality stone crushing plants and equipment and its spares to the entire satisfaction of our clients. Our products include jaw Crusher (Primary Crusher), Granulator (secondary crusher), roll crusher (bush type), belt conveyors and loaders in different sizes and designs according to the specifics requirements of customers. Our stone crushing plants range production from 20TPH to I50TPH according to the requirement of customer.

Ubh industries always supplies replacement parts, as well as regular services to our customer crushing plants in most states of India, but enjoy strong equity in Sikkim, North Bengal, Bhutan, Nepal and Assam. stone crusher machine can be used in crushing of wide range of material such as BAUXITE, CARBORUNDUM, (Silicon Carbide), GRANITE, CALCUIM, IRON ORE, MANGANESE, RIVER GRAVEL, LIME STONE, BLACK ROCK, COAL, COKE, QUARTZ.

Research and Development

We under stand the fact that to survive the stiff market competition, it is imperative for us to constantly upgrade the technology used by us for manufacturing our material handling equipment. To help us in this, we have established a modern R&D unit within our organization, which is equipped with the latest technology based instruments and equipment. These help our R&D professionals in carrying out various research projects in an effective and competitive manner.

After Sale Services

We provide efficient after sale services that is provided by our trained staff. We not only install the machines but also assist our clients with their first use. We ensure that our crusher's function properly and hence our team timely visits sites and attends to the complains, as well as provide timely servicing to the crushers. We also have in-store spare parts of each model and hence ensure perfect replacement of parts, if required.

Parts List

- Main Body

- Liver Pin

- Jaw stock (Lever)

- Jaw Plates (Reversible)

- Toggle Bearing

- Toggle Plates

- Fixed Plate (Reversible)

- Slide Plate

- Fly wheel (Flat)

- Brackets cover

- Bearing Brackets

- Eccentric shaft

- Pitman fitted roll brg.

- Fly wheel (V-grove)

- Pull back rod

- Spring

- Washer

- Fly Nut

- Wedge block & Toggle Block

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Ubh industries deal in high quality stone crushing plants and equipment and its spares to the entire satisfaction of our clients. Our products include jaw Crusher (Primary Crusher), Granulator (secondary crusher), roll crusher (bush type), belt conveyors and loaders in different sizes and designs according to the specifics requirements of customers. Our stone crushing plants range production from 20TPH to I50TPH according to the requirement of customer.

Ubh industries always supplies replacement parts, as well as regular services to our customer crushing plants in most states of India, but enjoy strong equity in Sikkim, North Bengal, Bhutan, Nepal and Assam. stone crusher machine can be used in crushing of wide range of material such as BAUXITE, CARBORUNDUM, (Silicon Carbide), GRANITE, CALCUIM, IRON ORE, MANGANESE, RIVER GRAVEL, LIME STONE, BLACK ROCK, COAL, COKE, QUARTZ.

Research and Development

We under stand the fact that to survive the stiff market competition, it is imperative for us to constantly upgrade the technology used by us for manufacturing our material handling equipment. To help us in this, we have established a modern R&D unit within our organization, which is equipped with the latest technology based instruments and equipment. These help our R&D professionals in carrying out various research projects in an effective and competitive manner.

After Sale Services

We provide efficient after sale services that is provided by our trained staff. We not only install the machines but also assist our clients with their first use. We ensure that our crusher's function properly and hence our team timely visits sites and attends to the complains, as well as provide timely servicing to the crushers. We also have in-store spare parts of each model and hence ensure perfect replacement of parts, if required.

Parts List

- Main Body

- Liver Pin

- Jaw stock (Lever)

- Jaw Plates (Reversible)

- Toggle Bearing

- Toggle Plates

- Fixed Plate (Reversible)

- Slide Plate

- Fly wheel (Flat)

- Brackets cover

- Bearing Brackets

- Eccentric shaft

- Pitman fitted roll brg.

- Fly wheel (V-grove)

- Pull back rod

- Spring

- Washer

- Fly Nut

- Wedge block & Toggle Block